Germany Takes the Lead in Europe's AI Manufacturing Race with Strategic Help from NVIDIA

In the rapidly evolving landscape of global manufacturing, artificial intelligence (AI) has emerged as a transformative force that is redefining how industrial economies operate, compete, and innovate. At the forefront of this shift is Germany—Europe’s traditional powerhouse in mechanical engineering, automotive production, and high-precision industrial manufacturing. As nations across the continent race to integrate AI into their economic engines, Germany’s unique fusion of technological heritage, skilled labor, and robust infrastructure provides a strong foundation for AI-driven transformation. Central to this evolution is the strategic role played by NVIDIA, the American semiconductor and AI computing giant, whose investments, partnerships, and cutting-edge technologies are helping Germany assert leadership in Europe’s AI manufacturing race.

Germany’s prominence in manufacturing is well established. For decades, it has been the industrial heart of Europe, exporting everything from cars and industrial machines to chemicals and electrical equipment. However, in a world increasingly defined by digital intelligence and automation, this traditional strength has faced growing pressure to modernize. The convergence of AI with manufacturing—termed “Industry 4.0” in the German context—has opened new pathways for efficiency, customization, and predictive performance. Yet achieving these gains requires more than incremental upgrades; it demands advanced computational capabilities, scalable infrastructure, and robust AI ecosystems. This is where NVIDIA's involvement becomes not only strategic but pivotal.

NVIDIA, originally renowned for its high-performance graphics processing units (GPUs), has emerged in recent years as a linchpin in the global AI ecosystem. With technologies that power everything from large language models to autonomous vehicles and digital twins, NVIDIA is uniquely positioned to support large-scale AI deployments. In Germany, the company has aligned itself with national priorities around smart manufacturing, AI sovereignty, and industrial competitiveness. Through partnerships with leading corporations like BMW, technology firms such as Siemens, and academic institutions including the Technical University of Munich, NVIDIA is helping to embed intelligence directly into the production processes that underpin Germany’s industrial economy.

The significance of this collaboration extends beyond the borders of Germany. Europe has long been viewed as trailing the United States and China in AI development and implementation. While European countries have excelled in regulatory innovation and ethics-centered AI discourse, they have struggled to match the computational and infrastructural might of their global rivals. Germany’s leadership in the AI manufacturing domain, bolstered by NVIDIA’s technological muscle, represents a potential shift in that narrative. By demonstrating that AI can be successfully and ethically integrated into complex industrial systems at scale, Germany is not only strengthening its own economic foundation but also offering a blueprint for the rest of Europe.

Moreover, Germany’s strategic embrace of AI is occurring at a time when global supply chains are being recalibrated due to geopolitical tensions, energy transitions, and labor shortages. As countries seek to secure their industrial sovereignty and reduce dependencies on distant suppliers, AI-enabled manufacturing becomes a key enabler of resilience and flexibility. Germany’s proactive investments in AI, cloud infrastructure, edge computing, and workforce upskilling are timely responses to these emerging global imperatives. And NVIDIA’s support—whether through AI data centers, Omniverse-powered simulation environments, or AI accelerator chips—is instrumental in ensuring that these investments translate into tangible outcomes.

This blog post will explore in depth how Germany is leveraging its industrial legacy and strategic alliances with AI leaders like NVIDIA to position itself at the forefront of Europe’s AI manufacturing transformation. It will begin by examining the state of German manufacturing and its evolving relationship with AI technologies. Then, it will analyze NVIDIA’s expanding role within the country, highlighting key partnerships and infrastructural initiatives. The discussion will broaden to contrast Germany’s approach with those of other European nations, followed by a critical look at the challenges and prospects that lie ahead. Through this lens, it becomes evident that Germany’s AI trajectory—powered in part by NVIDIA—is not just a national priority but a continental opportunity.

Germany’s Industrial Edge Meets AI Transformation

Germany has long been hailed as Europe’s industrial backbone. Its prowess in precision engineering, automotive manufacturing, mechanical tooling, and factory automation has elevated the country to a global leadership position in advanced manufacturing. For decades, Germany’s strength has rested on its deep reservoir of skilled labor, a comprehensive network of medium-sized enterprises (the “Mittelstand”), and a culture of industrial excellence. However, as artificial intelligence (AI) redefines how factories operate and how goods are produced, Germany’s industrial identity is undergoing a fundamental transformation. The convergence of AI and manufacturing—commonly referred to under the Industry 4.0 umbrella—has emerged as both a challenge and an opportunity for the German economy.

The concept of Industry 4.0 originated in Germany more than a decade ago as part of a national initiative to digitize industrial production. The vision was clear: leverage advanced technologies such as the Internet of Things (IoT), cyber-physical systems, and data analytics to create smart factories. In recent years, however, AI has emerged as the most transformative element within this vision, enabling capabilities that go far beyond traditional automation. From real-time quality inspection and autonomous robotics to predictive maintenance and generative design, AI applications are increasingly integrated into the German industrial landscape. These technologies not only optimize processes but also fundamentally reshape value chains by enabling adaptive manufacturing, greater customization, and more efficient resource use.

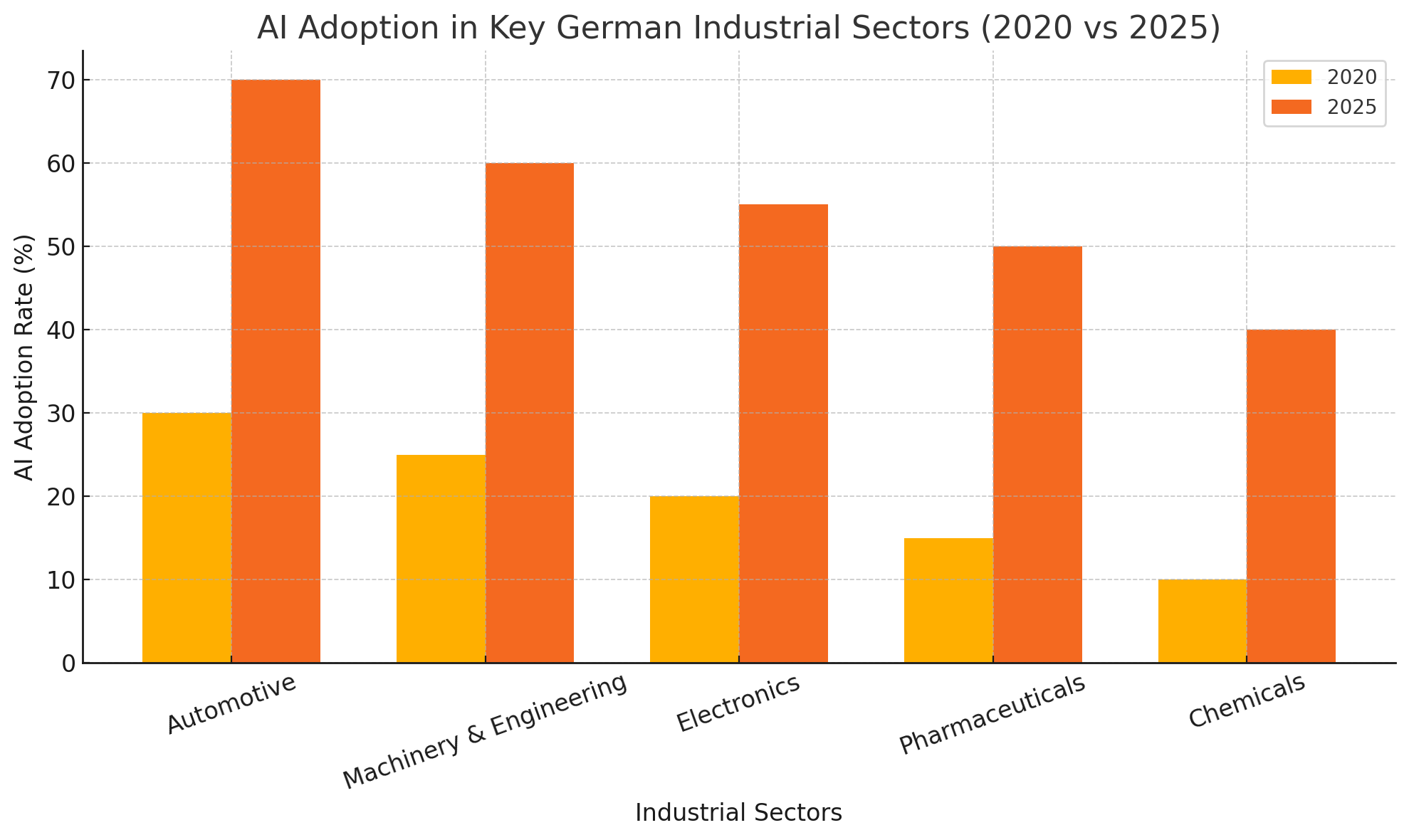

German industries, particularly in the automotive and mechanical engineering sectors, have been quick to recognize AI’s transformative potential. Leading firms such as BMW, Volkswagen, and Bosch are already deploying AI in various parts of their operations. For example, AI algorithms are used for visual inspection of parts on production lines, significantly improving defect detection rates while reducing human error. Similarly, predictive maintenance powered by machine learning is now being used to reduce downtime in complex machinery, which is critical in just-in-time manufacturing environments. AI is also being employed to optimize energy usage in industrial facilities, a key consideration as Germany seeks to reduce its carbon footprint.

The country’s Mittelstand—its network of highly specialized small and medium-sized enterprises—has also begun to embrace AI, though at a more measured pace. These companies, often family-owned and deeply embedded in local economies, form the backbone of German manufacturing. Many are now investing in AI tools to automate administrative tasks, streamline logistics, and enhance product design. However, barriers remain, including limited access to skilled AI professionals, high implementation costs, and data governance challenges. To address these gaps, the German government and various industrial consortia have introduced a series of initiatives aimed at democratizing AI access for SMEs, including subsidized training programs, AI accelerators, and shared innovation labs.

At the institutional level, Germany’s commitment to AI-driven manufacturing is reflected in the activities of research organizations like the Fraunhofer Society and the German Research Center for Artificial Intelligence (DFKI). These institutions act as important bridges between academic research and industrial application, conducting joint projects with manufacturers to develop AI systems that are both technically sophisticated and operationally relevant. For instance, Fraunhofer’s work on AI-enhanced robotics and digital twins is directly influencing how factories are planned, simulated, and optimized. Additionally, initiatives such as “Plattform Industrie 4.0”—a strategic alliance involving government, academia, and industry—serve as collaborative forums to advance AI integration at the national level.

One of the defining features of Germany’s AI manufacturing evolution is its emphasis on explainable and trustworthy AI. Unlike more permissive regulatory environments, Germany has taken a more cautious approach, seeking to balance innovation with ethical considerations. This is particularly relevant in sectors such as pharmaceuticals, aerospace, and automotive manufacturing, where safety and accountability are paramount. AI systems used in these settings must be interpretable and auditable, and German manufacturers are often required to maintain human oversight in critical decision-making processes. This commitment to ethical AI not only aligns with European regulatory frameworks but also enhances Germany’s reputation as a responsible global actor in industrial AI development.

Another critical driver of AI adoption in German manufacturing is the rising complexity of supply chains and the need for greater resilience. In the wake of global disruptions caused by the COVID-19 pandemic, geopolitical instability, and raw material shortages, German manufacturers have increasingly turned to AI to enhance visibility and agility in their supply networks. Advanced analytics and AI-driven forecasting tools are now being used to anticipate demand shifts, detect bottlenecks, and manage inventories more effectively. These capabilities are essential for maintaining production continuity and customer satisfaction in an increasingly uncertain global environment.

The energy transition, or Energiewende, is also catalyzing AI integration in German industry. As manufacturers seek to reduce emissions and transition to renewable energy sources, AI tools are being deployed to optimize energy consumption, integrate energy storage systems, and monitor emissions in real time. These efforts not only align with Germany’s climate goals but also help companies meet emerging global standards for environmental performance. For example, chemical and materials companies are leveraging AI to develop more sustainable production processes, such as low-emission cement and recyclable plastics.

Yet despite these advances, Germany’s AI manufacturing journey is far from complete. Structural challenges remain, including a shortage of AI talent, data interoperability issues, and the high capital costs associated with deploying AI at scale. The educational system is beginning to adapt, with universities expanding AI curricula and vocational schools offering specialized training. However, the pace of upskilling remains slower than required. In parallel, industrial companies must upgrade their IT and data infrastructures to fully benefit from AI applications—particularly in legacy systems that were not designed for digital integration.

The transformation of Germany’s manufacturing sector through AI is not occurring in isolation; it is embedded in a broader ecosystem of partnerships, platforms, and global collaborations. Among these, the role of multinational technology providers—particularly NVIDIA—is especially significant. By supplying the computational power, software tools, and AI research expertise necessary for industrial AI deployments, NVIDIA is enabling German manufacturers to move from pilot projects to production-scale applications. This collaboration represents a fusion of German engineering excellence and cutting-edge AI capabilities, setting a precedent for the next phase of industrial innovation in Europe.

Germany’s industrial edge, honed over decades, provides an ideal platform for AI integration. The combination of technical expertise, institutional support, and a willingness to evolve is positioning the country at the vanguard of AI-driven manufacturing transformation. As we shall explore in the next section, NVIDIA’s deepening involvement in Germany is not merely transactional; it is strategic, long-term, and mutually reinforcing. Together, they are crafting a vision of the future in which European industry can lead not only in production volume but also in intelligent, sustainable, and ethical manufacturing.

NVIDIA’s Strategic Investments and Partnerships in Germany

NVIDIA's expanding presence in Germany represents a strategic alignment between one of the world’s most influential AI technology companies and Europe’s leading industrial economy. As Germany seeks to accelerate its transition toward intelligent manufacturing, it has turned to global innovation partners capable of providing both the compute infrastructure and software platforms necessary to scale AI adoption. In this context, NVIDIA has become a pivotal enabler, helping Germany transform its traditional industrial base into a forward-looking AI-powered manufacturing powerhouse. Through a combination of infrastructure investments, joint innovation programs, and industry-specific AI applications, NVIDIA is helping to embed intelligence into the heart of Germany’s production ecosystems.

At the core of NVIDIA’s involvement in Germany is its provision of advanced computational infrastructure. As AI applications become increasingly complex and data-intensive, the need for high-performance computing (HPC) infrastructure has become urgent. In response, NVIDIA has partnered with several German cloud and telecommunications firms to build AI-ready data centers optimized for industrial workloads. One notable collaboration is with Deutsche Telekom, which is working with NVIDIA to deploy edge computing infrastructure capable of supporting latency-sensitive AI use cases in manufacturing. These data centers utilize NVIDIA’s H100 Tensor Core GPUs and Grace Hopper Superchips, enabling real-time processing of massive industrial datasets, including sensor data, simulation inputs, and predictive models.

Beyond infrastructure, NVIDIA has also launched joint research and development initiatives with leading German enterprises and academic institutions. One prominent example is the company’s ongoing partnership with BMW Group, which has deployed the NVIDIA Omniverse platform across its production planning processes. Omniverse allows BMW engineers to collaborate on digital twins of entire factories, simulating changes in layout, logistics, and assembly in real time. By enabling real-time simulation and optimization, Omniverse has not only accelerated BMW’s design cycles but also reduced operational costs and improved energy efficiency. The strategic value of this partnership extends beyond one company; it sets a template for how other German manufacturers can integrate AI and simulation into their own operations.

Another critical relationship is NVIDIA’s collaboration with Siemens, a global leader in industrial automation and digitalization. In 2022, the two companies announced a partnership aimed at connecting Siemens’ Xcelerator digital business platform with NVIDIA’s Omniverse. This integration enables seamless digital twin development for complex industrial systems, such as automated production lines and smart energy grids. Through this alliance, German factories can benefit from photorealistic simulations, AI-driven predictive analytics, and real-time decision-making tools. The result is not merely operational efficiency, but the emergence of a more agile and intelligent industrial ecosystem capable of adapting to market and supply chain disruptions.

NVIDIA’s commitment to Germany also includes significant investments in the country’s academic and research landscape. In partnership with the Technical University of Munich (TUM) and the German Research Center for Artificial Intelligence (DFKI), NVIDIA has helped establish AI research labs focused on advancing areas such as computer vision, robotics, and autonomous systems. These labs are not only producing cutting-edge academic work but also facilitating talent development and knowledge transfer between academia and industry. For Germany, this is especially valuable, as it addresses the national shortage of AI talent while also ensuring that academic research aligns with industrial needs.

Moreover, NVIDIA’s initiatives in Germany are closely tied to broader European ambitions around AI sovereignty and strategic autonomy. In alignment with the European Union’s “Digital Decade” agenda and Germany’s own AI Action Plan, NVIDIA is working to support the development of sovereign AI infrastructure that ensures data privacy, system interoperability, and regulatory compliance. For example, NVIDIA’s DGX SuperPOD systems are being used to support secure on-premise AI deployments in sectors like healthcare, manufacturing, and logistics, where compliance with Germany’s stringent data protection laws is non-negotiable. This localized approach to AI infrastructure is critical for maintaining trust and ensuring the long-term scalability of AI adoption across German industries.

In parallel, NVIDIA is engaging with Germany’s Mittelstand—the small and medium-sized enterprises that form the core of the country’s industrial ecosystem. Through joint innovation centers, accelerator programs, and AI workshops, NVIDIA is helping these firms overcome barriers to entry and explore AI’s potential. One such initiative is the AI Innovation Hub in Baden-Württemberg, developed in collaboration with regional economic development agencies. The hub provides hands-on access to NVIDIA’s platforms, including NVIDIA Metropolis for smart manufacturing and Clara for healthcare applications. These programs aim to reduce the complexity and cost of AI integration, enabling even the most traditional manufacturers to experiment with and deploy AI solutions.

The cumulative impact of these efforts is best understood in terms of ecosystem development. NVIDIA is not merely acting as a technology vendor but as an ecosystem orchestrator—connecting academia, industry, and government in a virtuous cycle of innovation. This approach aligns well with Germany’s tradition of cross-sector collaboration and its preference for long-term strategic planning. As a result, NVIDIA’s presence in Germany is catalyzing the emergence of what some observers have termed “AI Clusters”—geographically concentrated hubs of AI excellence that combine digital infrastructure, skilled labor, R&D facilities, and startup ecosystems. Regions such as Munich, Stuttgart, and Dresden are rapidly becoming focal points for AI-driven industrial transformation.

The importance of these clusters extends to global competitiveness. As Germany seeks to position itself as a global leader in AI-enhanced manufacturing, it must compete not only with traditional rivals like the United States and Japan but also with rising AI powers such as China and South Korea. NVIDIA’s technology provides a crucial edge in this race, enabling Germany to leapfrog legacy constraints and adopt future-ready manufacturing models. Whether through accelerated chip design, robotics simulation, or generative AI for industrial applications, NVIDIA’s contributions are pushing the boundaries of what is technologically and economically possible in German manufacturing.

NVIDIA’s long-term commitment to Germany is further evident in its localization strategy. The company has invested in German-language AI model support, user documentation, and compliance with national standards. This attention to localization ensures that German companies can adopt NVIDIA technologies without facing language, legal, or operational barriers. It also supports broader efforts by the German government to ensure digital inclusivity and reduce dependence on external platforms that may not align with European values or regulatory frameworks.

As AI becomes a foundational layer of global industry, NVIDIA’s role in Germany is likely to deepen. The company is already exploring opportunities in adjacent domains such as AI-enabled logistics, mobility-as-a-service, and autonomous manufacturing. These initiatives complement Germany’s own ambitions in smart mobility, energy-efficient production, and circular economy practices. In this context, NVIDIA is not simply helping Germany catch up in the AI race; it is helping the country redefine what leadership in industrial AI looks like.

In sum, NVIDIA’s investments and partnerships in Germany represent a multidimensional strategy that addresses infrastructure, innovation, talent, and trust. By embedding its technologies deep within Germany’s industrial and academic fabric, NVIDIA is facilitating a paradigm shift in how manufacturing is conceptualized and executed. The synergies between German engineering excellence and NVIDIA’s AI leadership are already yielding transformative results—and as we will explore in the next section, they are positioning Germany ahead of other European contenders in the race for AI-powered industrial dominance.

Europe’s AI Manufacturing Race: Germany vs. France, UK, and Nordics

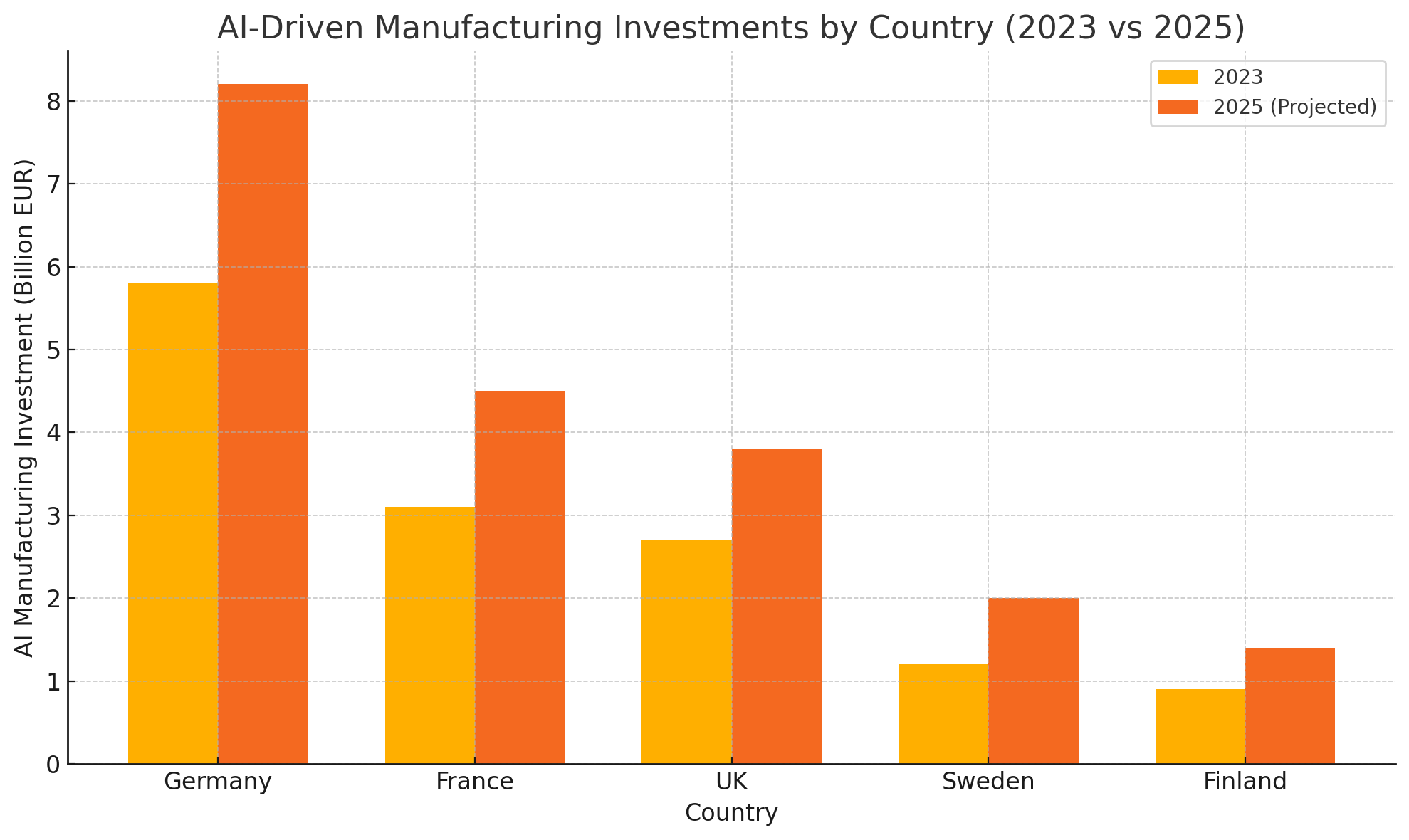

As artificial intelligence (AI) continues to reshape the manufacturing sector across Europe, nations are racing to integrate advanced technologies that can drive productivity, resilience, and competitiveness. Within this rapidly shifting landscape, Germany has emerged as the continental frontrunner, propelled by its robust industrial base and strategic alliances with leading AI firms such as NVIDIA. However, this leadership position is not uncontested. Countries such as France, the United Kingdom, and the Nordic states are also investing heavily in AI infrastructure, national strategies, and cross-sector collaborations to stake their claim in the AI-powered manufacturing future. Understanding how Germany compares to these regional peers offers critical insight into the dynamics of Europe’s AI industrial race and highlights the factors that differentiate strategic effectiveness from aspirational intent.

Germany’s head start stems largely from its traditional dominance in high-value manufacturing and its early adoption of the Industry 4.0 paradigm. Unlike some of its European counterparts that have emphasized AI primarily through research and digital services, Germany has grounded its AI strategy in physical production processes—automating factory floors, optimizing supply chains, and applying predictive analytics to precision engineering. The convergence of AI with Germany’s core strengths in automotive, machinery, and process industries has created a multiplier effect that enhances both technological capabilities and industrial productivity. With established infrastructure, a well-trained industrial workforce, and access to global partners like NVIDIA, Germany has successfully transitioned from pilot projects to scalable AI deployments.

In contrast, France has approached AI with a focus on centralized planning and sovereign digital infrastructure. The French government’s National AI Strategy, supported by billions of euros in funding, emphasizes AI for public services, health, and mobility. While France has cultivated strong academic institutions and launched AI research hubs such as INRIA and Hi! PARIS, its industrial application of AI—especially in manufacturing—has been less consistent. Companies like Dassault Systèmes and Schneider Electric have pioneered digital twin and automation technologies, but these efforts remain largely siloed and less integrated across industrial clusters than in Germany. Furthermore, France’s manufacturing base is smaller and less export-driven than Germany’s, limiting the scale at which AI innovation can be translated into global industrial leadership.

The United Kingdom, meanwhile, has carved a distinct niche in foundational AI research, fintech, and autonomous systems. Home to DeepMind and numerous AI startups, the UK has developed a strong innovation ecosystem supported by institutions such as the Alan Turing Institute. However, its AI investments have been skewed toward software and algorithmic development rather than hardware infrastructure and manufacturing deployment. In the absence of a dominant manufacturing sector comparable to Germany’s, the UK’s application of AI in industry has focused more on logistics, advanced materials, and aerospace components. While these are important areas, they do not offer the systemic industrial leverage needed to rival Germany’s breadth of AI deployment in production. Moreover, uncertainties stemming from Brexit have disrupted supply chains and reduced the UK’s participation in EU-funded research programs, limiting collaborative potential.

The Nordic countries—Sweden, Finland, Denmark, and Norway—present a different model characterized by sustainability, innovation, and digital readiness. Sweden, in particular, has demonstrated substantial progress in AI manufacturing through companies like Ericsson, Volvo, and ABB, which integrate AI into robotics, smart factories, and 5G-powered industrial platforms. Nordic strategies typically emphasize ethical AI, green manufacturing, and public-private partnerships. The Nordic approach is notable for its agility and focus on export-oriented high-tech manufacturing; however, the scale of their economies and industrial sectors is significantly smaller than Germany’s. As such, while the Nordics serve as important innovation testbeds, they lack the industrial mass to compete head-to-head with Germany in setting pan-European AI manufacturing standards.

Germany’s relative advantage is also reinforced by its integration into European and global supply chains. The country serves as a central hub for intra-European manufacturing coordination, particularly in the automotive and mechanical engineering sectors. This allows Germany to anchor EU-wide industrial initiatives, such as the Important Projects of Common European Interest (IPCEI), which fund collaborative innovation in microelectronics, batteries, and cloud infrastructure. Germany’s leadership in these programs ensures its strategic influence in shaping the future of AI-enhanced production across Europe. In contrast, other countries are often positioned as secondary nodes or specialized contributors, participating in pilot programs but not leading them.

NVIDIA’s role has further amplified this advantage. Through partnerships with German corporations and institutions, NVIDIA has embedded its AI technologies into the country’s manufacturing DNA. The resulting innovations—ranging from real-time factory simulations to intelligent supply chain management—are not easily replicable without equivalent industrial depth and ecosystem maturity. For instance, while a French or UK-based firm may adopt Omniverse for digital twin simulation, the impact is constrained by the availability of large-scale industrial deployments and supporting infrastructure. Germany, on the other hand, can operationalize these solutions at scale across hundreds of advanced manufacturing sites, making it the de facto benchmark for AI-driven industrial transformation in Europe.

The funding landscape also reflects Germany’s leadership. According to the European Investment Bank and the European Commission, Germany consistently receives the highest share of EU research and innovation funding in AI and industrial digitization. This financial support is augmented by national programs, such as the KI Strategie (AI Strategy) and the Zukunftsprogramm Industrie, which target SMEs, research labs, and regional innovation centers. These layered funding mechanisms enable a more coherent and comprehensive AI manufacturing strategy compared to the more fragmented or research-heavy approaches seen in France and the UK.

It is also worth noting that Germany’s cultural and regulatory alignment with AI implementation plays a facilitating role. The country’s engineering-centric mindset, combined with a rigorous approach to safety and quality, provides fertile ground for AI systems that require both precision and accountability. Moreover, German manufacturers are accustomed to compliance with complex industrial standards and certifications, making them well-equipped to implement explainable and transparent AI solutions. While ethical AI is a pan-European priority, Germany’s regulatory maturity gives it a practical edge in deploying compliant AI tools in safety-critical environments such as automotive production and pharmaceutical manufacturing.

Nonetheless, Germany’s leadership is not unchallenged. France continues to push for stronger AI sovereignty and is investing in national compute infrastructure, including plans to develop European alternatives to U.S. cloud and chip providers. The UK remains a formidable force in AI research, and Nordic countries continue to lead in agile and sustainable manufacturing innovation. Germany must therefore continue to evolve, expanding its talent pipeline, enhancing data interoperability, and scaling its AI cloud infrastructure to maintain its lead.

In conclusion, while the AI manufacturing race in Europe is intensifying, Germany presently holds a commanding position due to its industrial base, strategic partnerships, and operational maturity in deploying AI at scale. By contrast, France’s centralized planning model, the UK’s research-driven ecosystem, and the Nordics’ agile innovations each present valuable contributions but fall short of the scale and integration achieved by Germany. With continued investment, collaboration, and support from global technology leaders like NVIDIA, Germany is not only outpacing its European peers but also setting the trajectory for the continent’s future in AI-powered industry.

Challenges and Strategic Outlook

While Germany’s AI-powered manufacturing transformation—facilitated by strategic collaborations with NVIDIA—offers a model of industrial modernization, it is not without its significant challenges. As with any technological revolution, the path to widespread adoption and long-term sustainability is marked by structural, regulatory, and geopolitical hurdles. From talent shortages and infrastructural bottlenecks to questions of digital sovereignty and competitive threats from global peers, Germany must navigate a complex array of issues to maintain its leadership in AI-driven industrial innovation. At the same time, a forward-looking strategic outlook reveals that with targeted interventions and sustained collaboration, Germany is well-positioned to consolidate and extend its advantage.

Workforce and Skills Gap

One of the most pressing challenges Germany faces is the shortage of skilled labor equipped to operate and maintain AI-integrated industrial systems. Despite its longstanding reputation for vocational excellence and engineering talent, Germany is encountering a generational shift that has strained its labor pipeline. Many traditional manufacturing workers lack exposure to digital technologies, and upskilling initiatives—though expanding—have yet to reach the critical mass needed for nationwide transformation. Furthermore, the global competition for AI professionals places Germany at a disadvantage relative to English-speaking countries that attract top talent more easily.

To mitigate this gap, the German government and industry stakeholders have launched initiatives such as the “AI Campus” and the “Future Skills” program, focusing on technical retraining, STEM education, and university-industry partnerships. However, scale and speed remain concerns. Companies like NVIDIA can play a vital role in this domain by supporting AI education through specialized curricula, training certifications, and accelerator programs aimed at both students and working professionals. A broader cultural shift toward lifelong learning and digital literacy must also accompany technical interventions to ensure long-term labor market resilience.

Infrastructure and Data Interoperability

Germany’s progress in AI-enhanced manufacturing has also been hindered by infrastructural fragmentation. Many small and medium-sized enterprises (SMEs)—which constitute the backbone of German industry—lack the data infrastructure required to implement AI solutions effectively. Legacy systems, incompatible software platforms, and low levels of cloud adoption continue to impede seamless AI integration. This issue is compounded by varying standards across different sectors, making it difficult to scale AI models or replicate success stories across enterprises.

Efforts to standardize data formats and promote industrial interoperability are underway through initiatives like Gaia-X, a European project aimed at creating a federated and secure data infrastructure. However, real-world deployment remains slow, and many SMEs still operate in siloed environments. NVIDIA’s role in providing scalable, cloud-native AI platforms—such as Omniverse and DGX—can alleviate some of these limitations, but broader cooperation between government, industry, and platform providers is essential to achieve widespread system compatibility and data liquidity.

Energy Consumption and Environmental Constraints

As Germany intensifies its AI adoption across manufacturing, another significant challenge emerges: the environmental impact of compute-intensive AI workloads. High-performance data centers and edge computing systems consume large amounts of energy, often requiring consistent power delivery and sophisticated cooling infrastructure. This is particularly relevant in the context of Germany’s Energiewende—its ambitious transition away from nuclear and fossil fuels toward renewable energy sources. Balancing AI expansion with energy sustainability remains a difficult equation.

Addressing this issue involves not only technological innovations such as energy-efficient chips and optimized AI algorithms but also a shift in data center planning and renewable energy integration. NVIDIA has made strides in this area with the development of Grace Hopper-based architectures designed to improve power efficiency, but further advancements are necessary. Germany may also benefit from policies that incentivize low-carbon AI operations, including green AI certification, renewable-powered compute zones, and tax incentives for energy-efficient digital infrastructure.

Digital Sovereignty and Geopolitical Risks

The increasing reliance on foreign AI technologies—particularly from U.S.-based companies like NVIDIA—has triggered concerns around digital sovereignty and strategic autonomy. While NVIDIA's contributions have undoubtedly accelerated Germany’s industrial AI transformation, policymakers remain vigilant about dependency risks, particularly in areas involving sensitive data, critical infrastructure, and long-term technology access. The broader context of geopolitical tension, including U.S.-China tech rivalries and evolving export control regimes, further complicates the calculus.

Germany has responded by supporting the development of domestic AI capabilities, including local GPU manufacturing initiatives, national cloud platforms, and regulatory frameworks aimed at ensuring data protection and system transparency. At the European level, programs such as IPCEI-CIS (Important Projects of Common European Interest on Cloud Infrastructure and Services) and the Chips Act seek to strengthen the continent’s strategic autonomy. However, given the technological gap between European chipmakers and global leaders like NVIDIA, a balanced approach involving strategic partnerships rather than exclusion remains the most pragmatic path forward.

Innovation Diffusion and Regional Disparities

Another structural challenge is the uneven diffusion of AI innovation across Germany’s regions. While cities like Munich, Stuttgart, and Berlin are emerging as vibrant AI clusters with robust academic, startup, and industrial ecosystems, other regions—particularly in eastern and rural Germany—lag in terms of infrastructure, funding, and human capital. This spatial disparity threatens to create a two-tier industrial system, undermining national cohesion and overall economic resilience.

To address this, targeted regional policies are needed, including innovation grants, infrastructure subsidies, and AI testing zones in underserved areas. NVIDIA’s AI Innovation Hubs—when expanded beyond metropolitan centers—could act as key enablers in democratizing access to cutting-edge AI technologies. Moreover, public-private partnerships should be incentivized to ensure that regional universities and SMEs are integrated into national AI development efforts, rather than remaining isolated from mainstream innovation flows.

Strategic Outlook: Building a Sustainable AI Manufacturing Leadership

Despite these challenges, Germany’s strategic outlook for AI manufacturing remains promising. The country’s strengths in engineering, manufacturing discipline, and regulatory integrity provide a firm foundation upon which AI capabilities can be scaled. The ongoing collaboration with NVIDIA further strengthens this trajectory by ensuring access to world-class technology and global expertise.

Over the next five to ten years, Germany is likely to deepen its investments in autonomous manufacturing, generative AI for industrial design, AI-enabled quality assurance, and intelligent robotics. These domains offer high potential not only for productivity gains but also for positioning Germany as a global hub for responsible and ethical AI in industry. Strategic foresight will be critical—especially in anticipating future skill needs, aligning infrastructure with sustainability goals, and securing access to sovereign AI resources.

Furthermore, Germany’s leadership can serve as a model for the broader European Union. By sharing best practices, co-developing AI safety standards, and supporting regional innovation through pan-European initiatives, Germany has an opportunity to drive industrial cohesion across the continent. It can also help bridge the gap between regulatory ambition and practical deployment, offering a counterpoint to both the unregulated expansion of AI in other jurisdictions and the overly cautious approaches that may hinder innovation.

Finally, the continued partnership between German industry and global leaders like NVIDIA should evolve into more than just transactional alliances. As geopolitical dynamics shift and the next wave of AI innovation emerges—from neuromorphic computing to edge-native intelligence—these collaborations must be anchored in shared values, ethical alignment, and mutual long-term interests. Only through such inclusive and forward-thinking engagement can Germany truly secure its position as the nexus of AI-enhanced industrial excellence in Europe.

Conclusion

Germany’s ascension as Europe’s leader in AI-driven manufacturing marks a significant milestone in the continent’s broader digital and industrial evolution. At a time when global economies are being reshaped by artificial intelligence, automation, and geopolitical fragmentation, Germany has managed to leverage its traditional manufacturing strengths and forge a path that blends industrial precision with technological foresight. Central to this journey has been the strategic collaboration with NVIDIA—an AI powerhouse whose hardware, platforms, and research capabilities have played a foundational role in catalyzing transformation across Germany’s industrial sectors.

From automotive giants deploying AI-enhanced digital twins to medium-sized enterprises automating supply chains and predictive maintenance, Germany’s manufacturing landscape is undergoing a profound metamorphosis. The integration of AI is no longer confined to innovation labs or isolated pilot projects; it is rapidly becoming a core component of operational strategy and competitive positioning. This shift has been made possible by Germany’s deep reservoir of engineering talent, its networked approach to industrial collaboration, and its policy environment that seeks to balance innovation with accountability.

NVIDIA’s presence in Germany has amplified these advantages, providing not only the computational horsepower required for AI workloads but also enabling real-time simulation, generative design, and scalable AI infrastructure. Whether through Omniverse, DGX systems, or strategic partnerships with corporations and academic institutions, NVIDIA’s contributions have been instrumental in bridging the gap between AI theory and industrial application. Importantly, this collaboration reflects a broader model of how global technology firms can integrate into national innovation ecosystems without undermining digital sovereignty or ethical standards.

However, the road ahead is neither linear nor guaranteed. As this blog has outlined, Germany must still overcome significant challenges, including a shortage of AI-skilled labor, fragmented data infrastructure among SMEs, energy consumption concerns, and ongoing debates around technological dependency and sovereignty. These hurdles, while substantial, are not insurmountable. With targeted policy interventions, public-private cooperation, and sustained investment in education and infrastructure, Germany can address these vulnerabilities and build a more inclusive, resilient AI manufacturing ecosystem.

The strategic outlook remains highly favorable. As global demand grows for sustainable, intelligent, and adaptable manufacturing systems, Germany is uniquely positioned to export not just products, but also industrial best practices, AI standards, and ethical frameworks. The country’s emphasis on transparency, explainability, and accountability in AI deployment aligns well with emerging global norms, allowing Germany to shape the future of industrial AI not only through technology, but also through thought leadership.

Moreover, Germany’s leadership can act as a catalyst for Europe’s collective industrial competitiveness. By sharing infrastructure, co-developing standards, and collaborating on research with other EU member states, Germany can help create a unified European approach to AI in manufacturing—one that combines innovation with social responsibility and economic cohesion. This would position Europe as a credible third force in the global AI landscape, balancing the dominance of U.S. and Chinese tech ecosystems.

Looking ahead, the future of AI in manufacturing will be defined by agility, scalability, and trust. Germany’s partnership with NVIDIA exemplifies how these pillars can be achieved through collaboration, not isolation. As new frontiers emerge—from AI-powered robotics and quantum-enhanced simulations to decentralized edge intelligence—Germany must remain committed to adaptation, openness, and long-term vision.

In sum, the alliance between Germany’s industrial excellence and NVIDIA’s AI innovation is more than a convergence of strengths—it is a blueprint for how nations can transition into the next era of intelligent manufacturing. If sustained and expanded thoughtfully, it has the potential to redefine not only the future of German industry but also the trajectory of Europe’s role in the global AI economy.

References

- NVIDIA and BMW Group Expand Collaboration on Omniverse

https://blogs.nvidia.com/blog/bmw-nvidia-omniverse/ - Germany’s AI Strategy – Federal Ministry of Education and Research

https://www.bmbf.de/bmbf/en/research/digital-world/artificial-intelligence/artificial-intelligence.html - NVIDIA and Siemens Announce Partnership to Enable Industrial Metaverse

https://blogs.nvidia.com/blog/siemens-nvidia-industrial-metaverse/ - Fraunhofer Society – AI in Industry

https://www.fraunhofer.de/en/research/current-research/artificial-intelligence.html - BMW Uses NVIDIA Omniverse for Factory Digital Twins

https://developer.nvidia.com/blog/how-bmw-uses-omniverse-factory-digital-twins/ - Gaia-X: The Next Generation of Data Infrastructure for Europe

https://www.data-infrastructure.eu - EU Chips Act: Strengthening Europe’s Semiconductor Ecosystem

https://digital-strategy.ec.europa.eu/en/policies/european-chips-act - Technical University of Munich – AI Research Initiatives

https://www.tum.de/en/research/artificial-intelligence/ - Platform Industrie 4.0 – Germany’s Industrial AI Initiative

https://www.plattform-i40.de - European Commission – AI Policy and Investment

https://digital-strategy.ec.europa.eu/en/policies/artificial-intelligence